Turbo Compressor

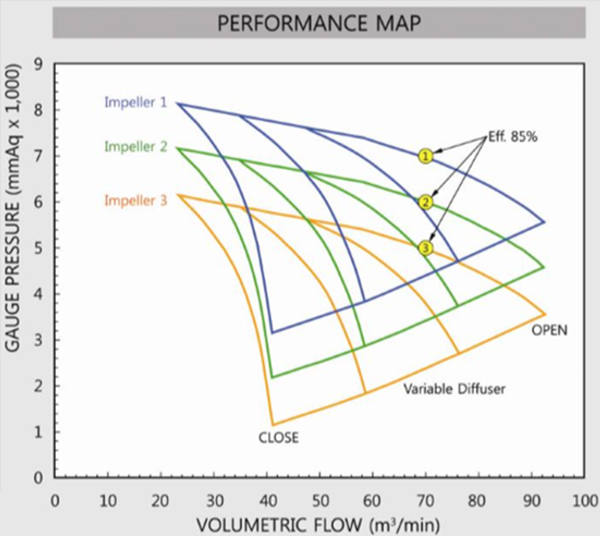

AIRGEN provides a customized impellers for each customer’s operating points, so that Aerodynamic efficiency is guaranteed from 80% to 85% at all operating points.

Turbo compressor (gear acceleration type)

-

Impeller 1 : Flow at main operating point-70, pressure-0.7

Impeller 2 : Flow at main operating point-70, pressure-0.6

Impeller 3 : Flow at main operating point-70, pressure-0.5

Compressor specification (gear acceleration type)

| Model |

Output(kW) |

Flow(㎥/min) |

Size |

| Min. |

Max. |

W |

L |

H |

| AGB-010 |

10 |

54 |

30 |

1470 |

2100 |

1300 |

| AGB-020 |

21 |

113 |

60 |

1470 |

2200 |

1450 |

| AGB-030 |

51 |

176 |

90 |

1470 |

2300 |

1545 |

| AGB-040 |

79 |

239 |

120 |

2100 |

2900 |

1975 |

| AGB-050 |

109 |

334 |

160 |

2100 |

3100 |

1975 |

| AGB-060 |

139 |

441 |

210 |

2250 |

3300 |

2250 |

| AGB-070 |

189 |

545 |

260 |

2250 |

3300 |

2250 |

| AGB-080 |

237 |

669 |

320 |

2250 |

3700 |

2250 |

| AGB-090 |

277 |

814 |

390 |

2350 |

4700 |

2750 |

| AGB-100 |

325 |

1020 |

490 |

2500 |

5250 |

3000 |

| AGB-110 |

393 |

1328 |

640 |

2500 |

5250 |

3000 |

| AGB-120 |

510 |

1852 |

940 |

3000 |

6000 |

3500 |

| MODEL |

AGB-010 |

| Output(kW) |

Min. |

10 |

| Max. |

54 |

| Flow(㎥/min) |

30 |

| Size |

W |

1470 |

| L |

2100 |

| H |

1300 |

| MODEL |

AGB-020 |

| Output(kW) |

Min. |

21 |

| Max. |

113 |

| Flow(㎥/min) |

60 |

| Size |

W |

1470 |

| L |

2200 |

| H |

1450 |

| MODEL |

AGB-030 |

| Output(kW) |

Min. |

51 |

| Max. |

176 |

| Flow(㎥/min) |

90 |

| Size |

W |

1470 |

| L |

2300 |

| H |

1545 |

| MODEL |

AGB-040 |

| Output(kW) |

Min. |

79 |

| Max. |

239 |

| Flow(㎥/min) |

120 |

| Size |

W |

2100 |

| L |

2900 |

| H |

1975 |

| MODEL |

AGB-050 |

| Output(kW) |

Min. |

109 |

| Max. |

334 |

| Flow(㎥/min) |

160 |

| Size |

W |

2100 |

| L |

3100 |

| H |

1975 |

| MODEL |

AGB-060 |

| Output(kW) |

Min. |

139 |

| Max. |

441 |

| Flow(㎥/min) |

210 |

| Size |

W |

2250 |

| L |

3300 |

| H |

2250 |

| MODEL |

AGB-070 |

| Output(kW) |

Min. |

189 |

| Max. |

545 |

| Flow(㎥/min) |

260 |

| Size |

W |

2250 |

| L |

3300 |

| H |

2250 |

| MODEL |

AGB-080 |

| Output(kW) |

Min. |

237 |

| Max. |

669 |

| Flow(㎥/min) |

320 |

| Size |

W |

2250 |

| L |

3700 |

| H |

2250 |

| MODEL |

AGB-090 |

| Output(kW) |

Min. |

277 |

| Max. |

814 |

| Flow(㎥/min) |

390 |

| Size |

W |

2350 |

| L |

4700 |

| H |

2750 |

| MODEL |

AGB-100 |

| Output(kW) |

Min. |

325 |

| Max. |

1020 |

| Flow(㎥/min) |

490 |

| Size |

W |

2500 |

| L |

5250 |

| H |

3000 |

| MODEL |

AGB-110 |

| Output(kW) |

Min. |

393 |

| Max. |

1328 |

| Flow(㎥/min) |

640 |

| Size |

W |

2500 |

| L |

5250 |

| H |

3000 |

| MODEL |

AGB-120 |

| Output(kW) |

Min. |

510 |

| Max. |

1852 |

| Flow(㎥/min) |

940 |

| Size |

W |

3000 |

| L |

6000 |

| H |

3500 |

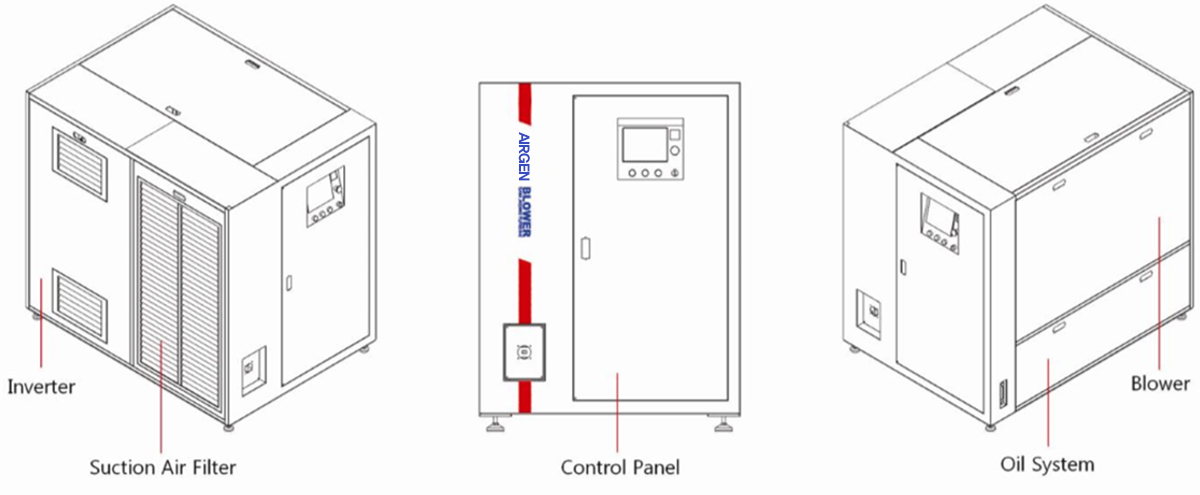

Turbo Compressor(High speed motor type)

Best performance in class, energy savings, and efficiency

AIRGEN's HTB series is a high-efficiency product using a high-speed motor(BLDC), inverter and hybrid bearing. It is more efficient than existing products and has less noise and vibration, so it can innovatively improve the working environment.

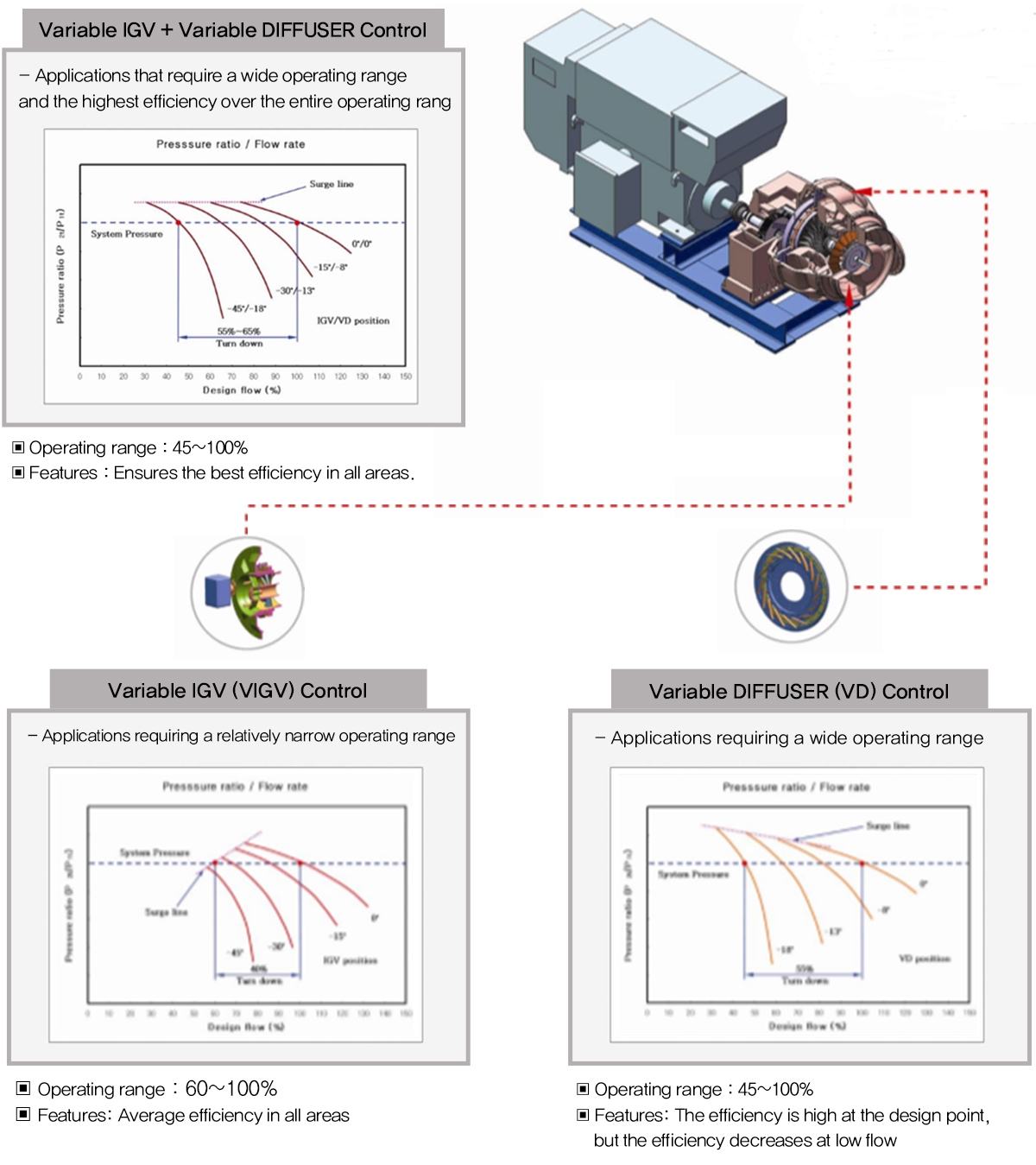

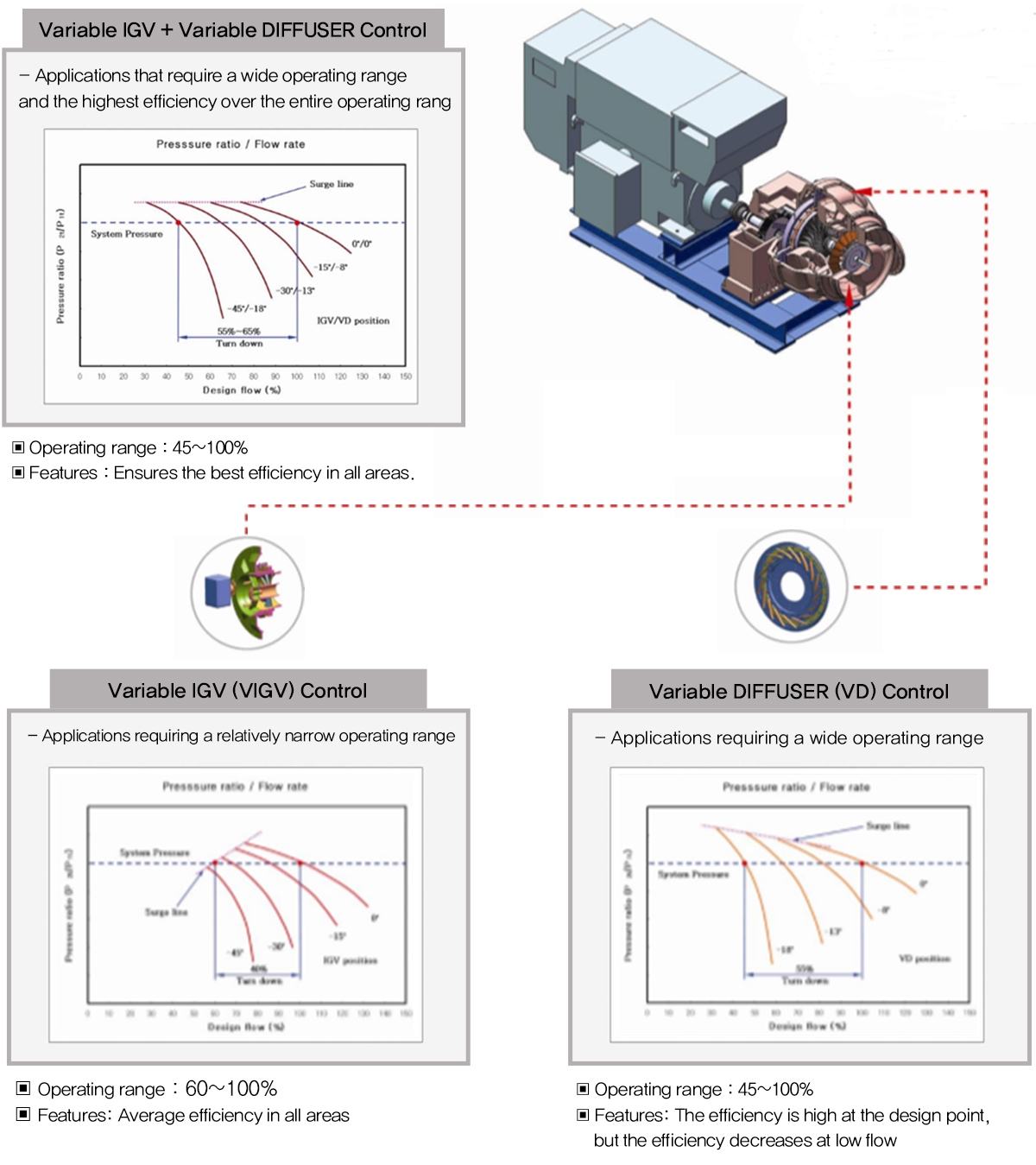

Provides the world largest air volume range and saves energy across the entire range, 'Best in class'

By controlling the inverter and the variable discharge diffuser in combination, the efficiency is high, the air volume range is available in 30~100%, and high energy savings can be obtained at any operating point within the control range.

| Flow control range |

30% |

40% |

70% |

100% |

| Aerodynamic efficiency |

70~80% and above |

80% and above |

84% and above |

84% and above |

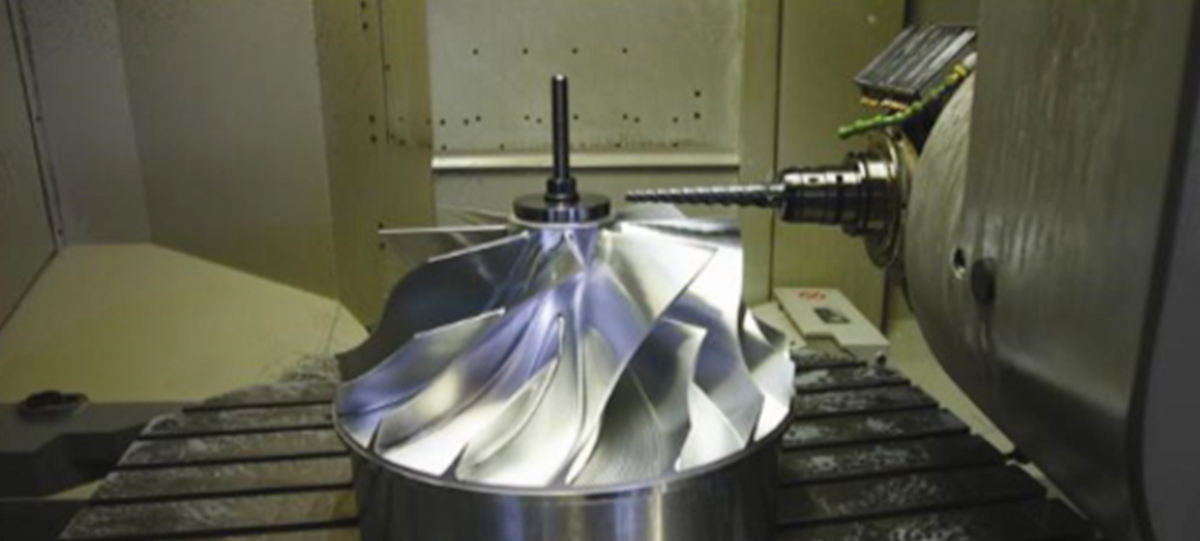

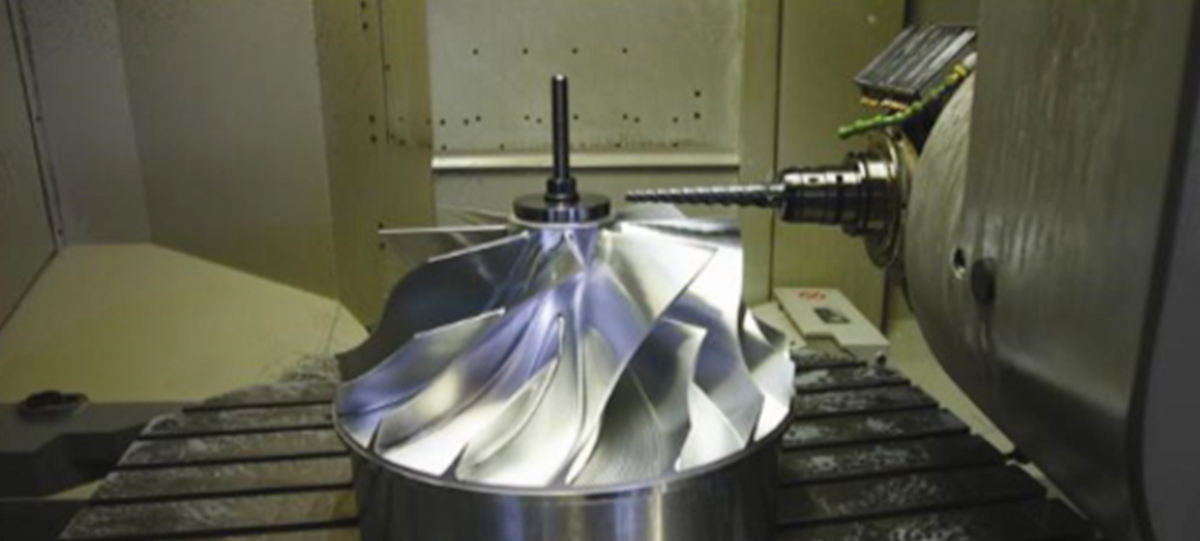

Customized high-efficiency impeller & scroll 'Best in class'

Unlike the existing makers, it provides the best aerodynamic efficiency by manufacturing Impeller (5-axis machining) and Scroll (casting) that meet the customer's specifications (pressure & flow rate).

Outstanding performance

Superior compression efficiency

The patented hybrid bearing maximizes aerodynamic efficiency by minimizing gap between impeller and shroud. (Air bearings are difficult to minimize gap between impeller and shroud (tip clearance) due to their characteristics, resulting in 5~9% loss).

Outstanding Motor Performance

The patented technology realizes cooling of the motor stator and rotor at the same time, and the use of a large-diameter motor rotor provides high torque and high efficiency. Efficiency is high due to the narrow gap between the stator and the rotor by using the patented rotor structure.

| Items |

AIRGEN |

Competitor |

| Aerodynamic efficiency |

82~86% |

75~79% |

| Inverter |

95~97% |

93~95% |

| Motor |

93~95% |

93~95% |

| System efficiency |

72~79% |

65~70% |

| Operating range |

30~100% |

70~100% |

| Type |

Model |

Scroll |

Power (kw) |

Magnet |

Flow Rate

(㎥/min) |

Weight

(kg) |

Size

(mm)

|

| Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

W |

L |

H |

| 1 |

HTB-020-030 |

10G |

20G |

10 |

30 |

1 |

2 |

10 |

30 |

600 |

1100 |

1400 |

1480 |

| 2 |

HTB-020-050 |

10G |

20G |

30 |

50 |

1 |

2 |

30 |

60 |

700 |

1100 |

1400 |

1480 |

| 3 |

HTB-030-075 |

20G |

30G |

50 |

75 |

2 |

3 |

60 |

90 |

800 |

1100 |

1400 |

1480 |

| 4 |

HTB-030-125 |

20G |

30G |

75 |

125 |

2 |

3 |

60 |

90 |

900 |

1100 |

1650 |

1480 |

| 5 |

HTB-040-125 |

30G |

40G |

125 |

3 |

4 |

90 |

120 |

1000 |

1200 |

1650 |

1580 |

| 6 |

HTB-040-150 |

30G |

40G |

150 |

3 |

4 |

90 |

120 |

1200 |

1200 |

1850 |

1580 |

| 7 |

HTB-050-175 |

40G |

50G |

175 |

4 |

5 |

120 |

160 |

1500 |

1400 |

2000 |

1680 |

| 8 |

HTB-050-200 |

40G |

50G |

200 |

4 |

5 |

120 |

160 |

1800 |

1400 |

2200 |

1680 |

| 9 |

HTB-060-225 |

50G |

60G |

225 |

5 |

6 |

160 |

210 |

2200 |

1600 |

2400 |

1880 |

| 10 |

HTB-060-250 |

50G |

60G |

250 |

5 |

6 |

160 |

210 |

2500 |

1600 |

2400 |

1880 |

| 11 |

HTB-070-275 |

60G |

70G |

275 |

5 |

6 |

210 |

260 |

3000 |

1800 |

2600 |

1880 |

| Type |

1 |

| MODEL |

HTB-020-030 |

| Scroll |

Min. |

10G |

| Max. |

20G |

| Power (kw) |

Min. |

10 |

| Max. |

30 |

| Magnet |

Min. |

1 |

| Max. |

2 |

| Flow Rate (㎥/min) |

Min. |

10 |

| Max. |

30 |

| Weight (kg) |

600 |

| Size (mm) |

W |

1100 |

| L |

1400 |

| H |

1480 |

| Type |

2 |

| MODEL |

HTB-020-050 |

| Scroll |

Min. |

10G |

| Max. |

20G |

| Power (kw) |

Min. |

30 |

| Max. |

50 |

| Magnet |

Min. |

1 |

| Max. |

2 |

| Flow Rate (㎥/min) |

Min. |

30 |

| Max. |

60 |

| Weight (kg) |

700 |

| Size (mm) |

W |

1100 |

| L |

1400 |

| H |

1480 |

| Type |

3 |

| MODEL |

HTB-030-075 |

| Scroll |

Min. |

20G |

| Max. |

30G |

| Power (kw) |

Min. |

50 |

| Max. |

75 |

| Magnet |

Min. |

2 |

| Max. |

3 |

| Flow Rate (㎥/min) |

Min. |

60 |

| Max. |

90 |

| Weight (kg) |

800 |

| Size (mm) |

W |

1100 |

| L |

1400 |

| H |

1480 |

| Type |

4 |

| MODEL |

HTB-030-125 |

| Scroll |

Min. |

20G |

| Max. |

30G |

| Power (kw) |

Min. |

75 |

| Max. |

125 |

| Magnet |

Min. |

2 |

| Max. |

3 |

| Flow Rate (㎥/min) |

Min. |

60 |

| Max. |

90 |

| Weight (kg) |

900 |

| Size (mm) |

W |

1100 |

| L |

1650 |

| H |

1480 |

| Type |

5 |

| MODEL |

HTB-040-125 |

| Scroll |

Min. |

30G |

| Max. |

40G |

| Power (kw) |

Min. |

125 |

| Max. |

125 |

| Magnet |

Min. |

3 |

| Max. |

4 |

| Flow Rate (㎥/min) |

Min. |

90 |

| Max. |

120 |

| Weight (kg) |

1000 |

| Size (mm) |

W |

1200 |

| L |

1650 |

| H |

1580 |

| Type |

6 |

| MODEL |

HTB-040-150 |

| Scroll |

Min. |

30G |

| Max. |

40G |

| Power (kw) |

Min. |

150 |

| Max. |

150 |

| Magnet |

Min. |

3 |

| Max. |

4 |

| Flow Rate (㎥/min) |

Min. |

90 |

| Max. |

120 |

| Weight (kg) |

1200 |

| Size (mm) |

W |

1200 |

| L |

1850 |

| H |

1580 |

| Type |

7 |

| MODEL |

HTB-050-175 |

| Scroll |

Min. |

40G |

| Max. |

50G |

| Power (kw) |

Min. |

175 |

| Max. |

175 |

| Magnet |

Min. |

4 |

| Max. |

5 |

| Flow Rate (㎥/min) |

Min. |

120 |

| Max. |

160 |

| Weight (kg) |

1500 |

| Size (mm) |

W |

1400 |

| L |

2000 |

| H |

1680 |

| Type |

8 |

| MODEL |

HTB-050-200 |

| Scroll |

Min. |

40G |

| Max. |

50G |

| Power (kw) |

Min. |

200 |

| Max. |

200 |

| Magnet |

Min. |

4 |

| Max. |

5 |

| Flow Rate (㎥/min) |

Min. |

120 |

| Max. |

160 |

| Weight (kg) |

1800 |

| Size (mm) |

W |

1400 |

| L |

2200 |

| H |

1680 |

| Type |

9 |

| MODEL |

HTB-060-225 |

| Scroll |

Min. |

50G |

| Max. |

60G |

| Power (kw) |

Min. |

225 |

| Max. |

225 |

| Magnet |

Min. |

5 |

| Max. |

6 |

| Flow Rate (㎥/min) |

Min. |

160 |

| Max. |

210 |

| Weight (kg) |

2200 |

| Size (mm) |

W |

1600 |

| L |

2400 |

| H |

1880 |

| Type |

10 |

| MODEL |

HTB-060-250 |

| Scroll |

Min. |

50G |

| Max. |

60G |

| Power (kw) |

Min. |

250 |

| Max. |

250 |

| Magnet |

Min. |

5 |

| Max. |

6 |

| Flow Rate (㎥/min) |

Min. |

160 |

| Max. |

210 |

| Weight (kg) |

2500 |

| Size (mm) |

W |

1600 |

| L |

2400 |

| H |

1880 |

| Type |

11 |

| MODEL |

HTB-070-275 |

| Scroll |

Min. |

60G |

| Max. |

70G |

| Power (kw) |

Min. |

275 |

| Max. |

275 |

| Magnet |

Min. |

5 |

| Max. |

6 |

| Flow Rate (㎥/min) |

Min. |

210 |

| Max. |

260 |

| Weight (kg) |

3000 |

| Size (mm) |

W |

1800 |

| L |

2600 |

| H |

1880 |

EGR Blower

EGR (Exhaust Gas Recirculation) is a method of achieving NOx reduction in MAN B&W two stroke marine diesel engines to comply with IMO's Tier III NOx regulations of MARPOL Annex VI. The EGR blower is one of the critical components required to enable the EGR process to reduce nitrogen oxides (NOx) by cooling and purifying the exhaust gases and recirculating them to the engine combustion air intake to lower the stoichiometric combustion temperature.

AIRGEN EGR-Blower is developed according to MAN-ES requirements based on more than 20 years of experience in turbomachinery, and will be supplied to the relevant licensees through MAN-ES for the time being.

Unlike the existing commercial products, AIRGEN EGR-Blower integrates all functions so that reduces the size to 1/3.

- minimize the size by increasing rpm more than twice

- Minimize the size by replacing the air-cooled VFD inverter with water-cooled

- Inverter and electromagnetic wave filter are integrated inside of EGR-Blower casing

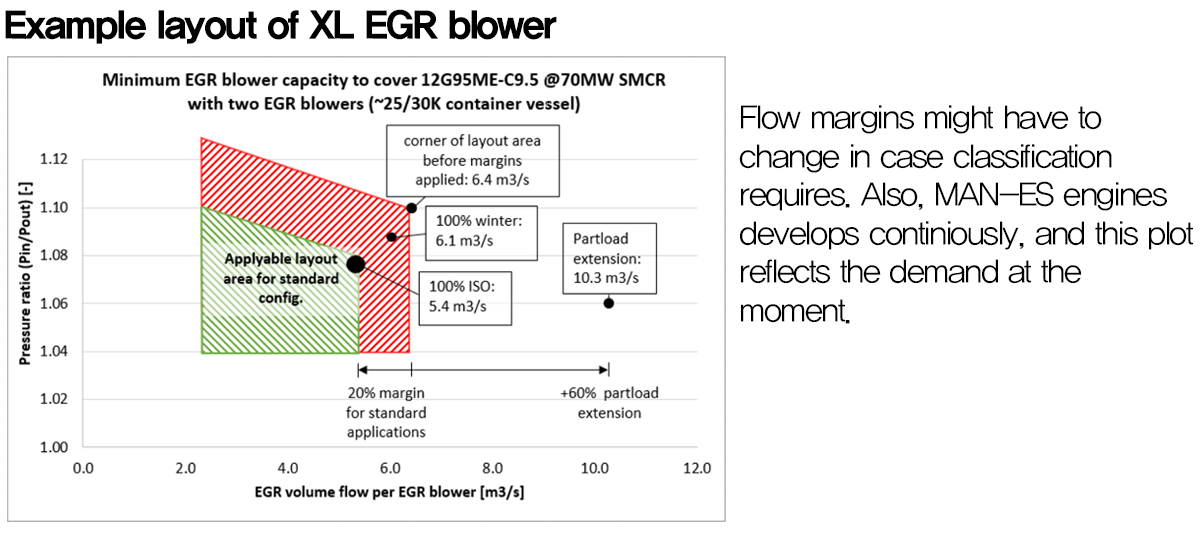

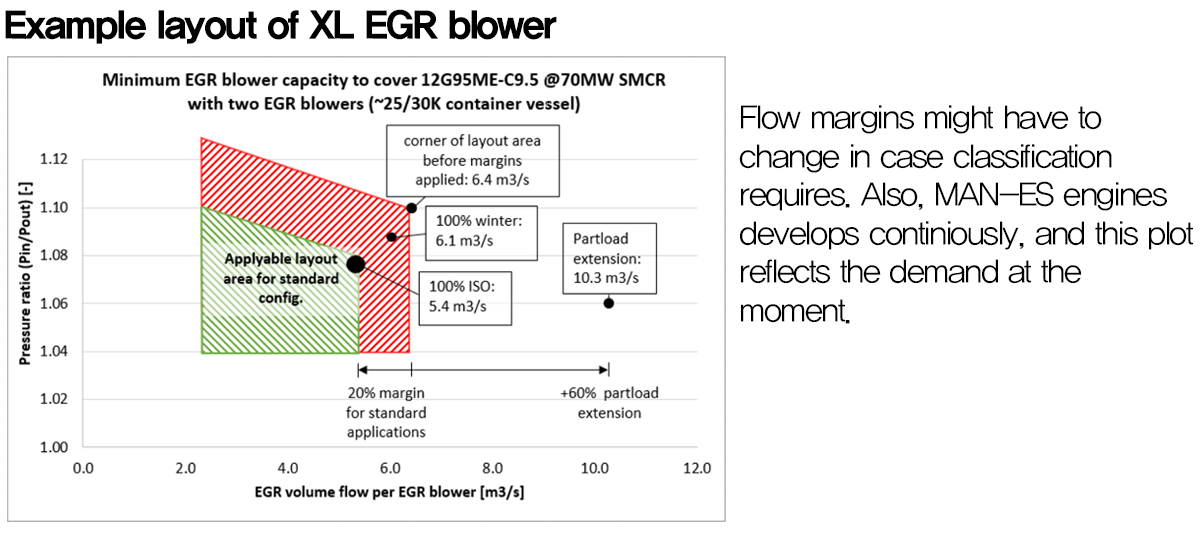

Design margine of EGR blower:

- 20% margin for standard application

- 60% margin at part load extension

Products will be commercialized at the end of 2020

| Size |

Model |

Maximum flow(㎥/sec.)

|

| XL |

EGR-B6.6 |

6.6 |

| L |

EGR-B4.5 |

4.5 |

| M |

EGR-B2.5 |

2.5 |

- Normal delivery date: 4 months after order

- First product delivery date: 6 months after order